VIP member

Sanitary cam rotor pump

Stainless steel cam rotor pump, universal transfer pump, three bladed pump, butterfly pump, shoe sole pump Product introduction: Product description:

Product details

| Stainless steel cam rotor pump, universal transfer pump, three bladed pump, butterfly pump, shoe sole pump |

|

Product Introduction: |

Product Description:

Universal conveying pump, also known as colloid pump, rotary pump, three leaf pump, sole pump, Roots pump, stainless steel rotary pump, cam pump, yeast pump, butterfly pump, three leaf pump, sole pump, medicine pump, hot-melt colloid pump, particle colloid pump, slag pump, protein residue pump, high concentration slurry pump, etc., is widely used in industries such as food, beverage, chemical, pharmaceutical, etc. Due to the unique rotor shape and high precision requirements of the pump, there are few successful manufacturers in China, and many users can only purchase imported equipment. To change this unfavorable situation, our factory organized technical personnel to tackle the problem, carefully developed a rotor curve design program, and inputted it into the machining center for precision machining. This ensures the high precision and strict consistency requirements of the key components of the pump. Scope of application: Dairy products: yogurt, fresh cream, ice cream, cheese cubes, and whey. Beverages: beer, malt extract, yeast, soda, fruit concentrate, fruit juice drinks. Food: tomato sauce, fruit puree, vegetable paste, pudding, jam, jelly, seasoning, fruit filling, sweetener, yeast puree, salad dressing, facial pastry, minced meat, minced meat, cooking oil and cooking oil. Candy: syrup, cream filling, chocolate. Cosmetics: face cream and lotion, hair gel, hair dye, essence oil. Medications: pill paste, paste, emulsion, ointment. Makeup products: fats, solvents, resins and polymers, dyes. Features: ·All parts in contact with the medium (material) are made of stainless steel (material SUS304, AISI316, 316L), which fully complies with hygiene standards. ·Suitable for conveying media (materials) with high viscosity, concentration, and any particle content. ·Suitable for temperatures ranging from -30 ℃ to+180 ℃. ·High pressure (outlet pressure: 0.3-0.6MPa, maximum pressure when viscosity is 3000.000-5000.000CP: 0.8-1.5MPa), suitable for long-distance and high resistance quantitative transportation. ·The speed is low, usually between 200rpm and 600rpm, and the material conveyed by it maintains its original quality without any physical or chemical reactions. ·There is no contact between rotors, and there is no wear and tear even after long-term use. The operation is smooth, so the noise is low. ·Easy to fold, convenient to clean, and maintain hygiene and cleanliness. To achieve perfect results, please ask the customer to decide on the following points when selecting a pump: 1. The name of the conveying medium or liquid; 2. The viscosity and temperature of the medium; 3. Need to transport head, pressure, and flow rate; 4. The number and size of particles contained in the medium; 5. Selection of interfaces (clamps, threads, flanges). |

Main technical parameters: |

| model | Motor power (kw) | Displacement per face (L) | Speed range (r/min) | Corresponding flow rate (L/H) |

Imported pipe diameter (mm) |

| ZB3A-3 | 0.55 | 3 | 200-500 | 300-800 | 25/DN20 |

ZB3A-6 |

0.75 | 6 | 200-500 | 650-1600 | 25/DN20 |

ZB3A-8 |

1.5 | 8 | 200-500 | 850-2160 | 38/DN40 |

ZB3A-12 |

2.2 | 12 | 200-500 | 1300-3200 | 38/DN40 |

ZB3A-20 |

3 | 20 | 200-500 | 2100-5400 | 51/DN50 |

ZB3A-30 |

4 | 30 | 200-500 | 3200-6400 | 51/DN50 |

ZB3A-36 |

4 | 36 | 200-400 | 3800-7600 | 63/DN65 |

ZB3A-52 |

5.5 | 52 | 200-400 | 5600-11000 | 76/DN80 |

ZB3A-66 |

7.5 | 70 | 200-400 | 7100-14000 | 63/DN65 |

ZB3A-78 |

7.5 | 78 | 200-400 | 9000-18000 | 76/DN80 |

ZB3A-100 |

11 | 100 | 200-400 | 11000-21600 | 89/DN80 |

ZB3A-135 |

15 | 135 | 200-400 | 15000-30000 | 89/DN80 |

ZB3A-160 |

18.5 | 160 | 200-400 | 17000-34000 | 89/DN80 |

ZB3A-200 |

22 | 200 | 200-400 | 21600-43000 | 89/DN80 |

| ZB3A-300 | 30 | 300 | 200-400 | 31600-63000 | 102/DN100 |

Note: The flow range in the table refers to the data measured when the medium is "water". The speed regulation adopts stepless variable pole or variable frequency drive, with a speed range of 200-900rpm. When conveying high viscosity concentrated liquid, the power range of the motor is increased. The data in this table is subject to change without prior notice, and the correct parameters are based on the actual product provided. |

Product Structure: |

Butterfly rotor pump: Due to the use of a butterfly rotor, in addition to the characteristics of a general rotor pump, it has certain advantages in conveying materials with high viscosity and larger particles, and can effectively transport particularly viscous materials. Single butterfly curve rotor pump (granular rotor pump): This series of pumps is specially designed and manufactured to solve the problem of transporting materials containing large particles. Its unique shape and curve form enable it to have unparalleled advantages over other pumps when transporting materials containing large particles. During the material transportation process, it can effectively avoid particle damage and is the first choice for pumps transporting materials containing particles. |

|

| Selection of transmission:

|

Motor+fixed ratio reducer: This transmission method is simple and the rotor speed is constant This also determines the non adjustability of traffic. Motor+mechanical friction type continuously variable transmission: This type of transmission relies on manual adjustment to achieve speed change, and its characteristics are safe and reliable, high torque, and continuously adjustable flow rate The disadvantage is non automatic adjustment, which is more complicated. The speed regulation must be carried out during operation and cannot be adjusted while the machine is stopped. Please refer to the manufacturer's user manual for its use and maintenance specifications. Variable frequency motor+frequency converter: This method can achieve automatic adjustment of speed, that is, achieve stepless adjustment of flow rate Its advantages are high degree of automation and large low-speed torque; The disadvantage is that the price of the frequency converter is relatively high. Please refer to the manufacturer's user manual for its usage and maintenance specifications. Single butterfly curve rotor pump, granular rotor pump |

|

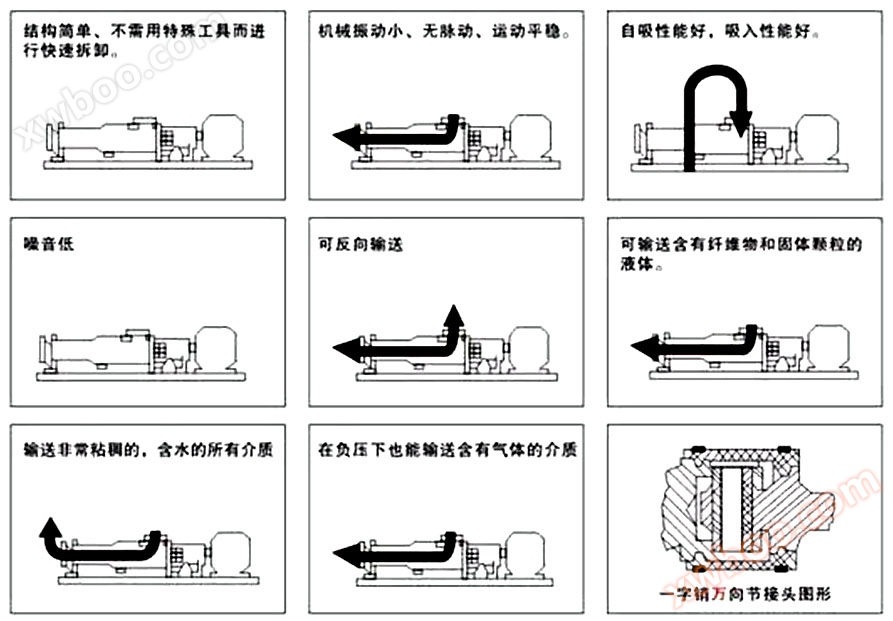

Screw pumps have the following advantages: |

| Compared with centrifugal pumps, screw pumps do not require valves and have a stable linear flow rate;

Compared with plunger pumps, screw pumps have stronger self-priming ability and higher suction height; Compared with diaphragm pumps, screw pumps can transport various mixed impurities, such as media containing gas and solid particles or fibers, as well as various corrosive substances; Compared with gear pumps, screw pumps can transport high viscosity substances; Unlike plunger pumps, diaphragm pumps, and gear pumps, screw pumps can be used for drug filling and metering. |

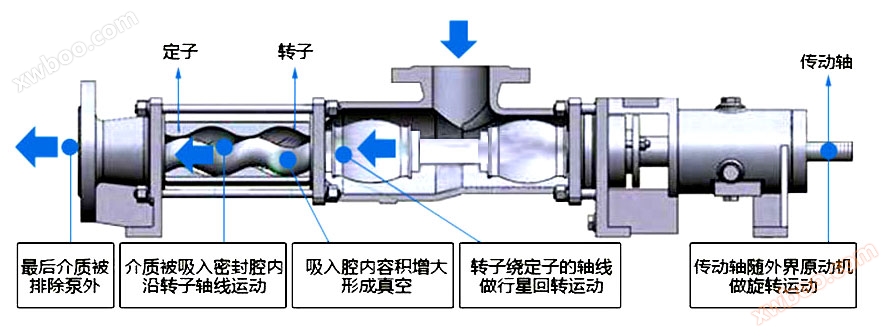

Working principle of screw pump: |

|

Rod pump belongs to the category of push type positive displacement pump, with the main components being rotor and stator. The rotor is a screw with a large lead, high tooth height, and small inner diameter, while the stator is matched with a double headed spiral and screw sleeve, creating a space for storing the medium between the rotor and stator. When the rotor operates inside the stator, the medium moves axially from the suction end to the discharge end.

From the following working principle, it can be seen that screw pumps have the following advantages: 1. Wide range of pressure and flow. The pressure is about 3.4-340 kgf/cm2, and the flow rate can reach 18600 cm3/min; 2. Wide range of types and viscosities of liquids that can be transported; 3. Due to the low inertia force of the rotating components inside the pump, a high rotational speed can be used; 4. Good inhalation performance and self-priming ability; 5. Uniform and continuous flow, low vibration, and low noise; Compared to other rotary pumps, it is less sensitive to incoming gases and pollutants; 7. The structure is solid and easy to install and maintain. The disadvantage of screw pumps is that the processing and assembly requirements for screws are relatively high; The performance of the pump is sensitive to changes in the viscosity of the liquid. |

|

Product details: |

|

Common faults and solutions: |

serial number |

Fault Type

|

Possible reasons |

solution |

1 |

The screw pump does not move |

The fit between the rotor and stator is too tight; The voltage is too low; The viscosity of the medium is too high. |

Use tools and manpower to rotate the pump a few times; Pressure regulation; Diluted material solution. |

2 |

Screw pump does not produce liquid |

The rotation direction is incorrect; There is a problem with the suction pipe; The viscosity of the medium is too high; Damage to the rotor, stator or transmission components; Foreign matter blockage inside the pump. |

Adjust the rotation direction; Check for leaks and open the inlet and outlet valves; Dilution solution; Check and replace damaged components to eliminate foreign objects. |

3 |

Insufficient traffic |

Pipeline leakage; Valves are not fully opened or partially blocked; The speed is too low; Rotation and stator wear. |

Inspect and repair pipelines; Open all gates and remove blockages; Adjust the speed; Replace damaged parts. |

4 |

Insufficient pressure |

Wear of rotor and stator. |

Replace the rotor and stator |

5 |

Motor overheating |

Motor malfunction; Excessive export pressure and motor overload; The motor bearings are damaged. |

Check the motor and eliminate its faults; Adjust the pressure by changing the opening of the outlet valve; Replace damaged parts. |

6 |

Rapid decrease in flow pressure |

Sudden blockage or leakage of pipelines; The stator is severely worn; Sudden change in liquid viscosity; The voltage suddenly drops. |

Eliminate blockages or seal pipelines; Replace the stator rubber; Change liquid viscosity or motor power; Adjust the pressure. |

7 |

A large amount of liquid leaked from the shaft seal |

Soft packing wear. |

Tighten or replace the packing. |

Installation instructions: |

Pay attention to the direction of the motor to prevent reverse rotation. A detachable pipeline slightly longer than the stator should be installed before the liquid outlet to facilitate the replacement of the stator. Keep the inlet of the pump in the vertical direction and the outlet in the horizontal direction, which can make the seal work in a negative pressure state and reduce the pressure in the sealing chamber. Rotation direction: Rotate counterclockwise when viewed from the exit direction. The pipeline should be equipped with support points, as the inlet and outlet flanges (pipeline) of the pump cannot bear the weight of the pipeline. The pipeline must be cleaned thoroughly before installation to prevent foreign objects from damaging the stator and rotor and causing blockage. The diameter of the pipeline should match the diameter of the pump as much as possible. A too small inlet diameter can cause insufficient feeding to the pump, which in turn affects the pump's discharge volume and output pressure. In severe cases, it can cause vibration of the pipeline and early damage to the stator. A too small outlet diameter can cause a loss of outlet pressure. For shaft seals that use mechanical seals, attention should be paid to adding clean water, lubricating oil, or other coolant. For single end sealed shaft seals, if the conveyed medium is viscous and prone to solidification and crystallization, the mechanical seal should be cleaned after the pump stops working to ensure its normal operation. There is an imperial pipe thread interface on both sides of the sealed box, and a random outlet throttling joint is also provided to directly connect the inlet pipeline of the circulating liquid to the sealed box. And connect the outlet throttling joint on its outlet side (which is crucial for maintaining a certain pressure inside the sealed adaptability box), and then connect it to the outlet pipeline. When starting up, the circulating fluid should be started first, and then the pump should be started; When stopping the machine, the pump should be stopped first, and then the circulating fluid should be turned off. |

|

Online inquiry